3D PRINTING

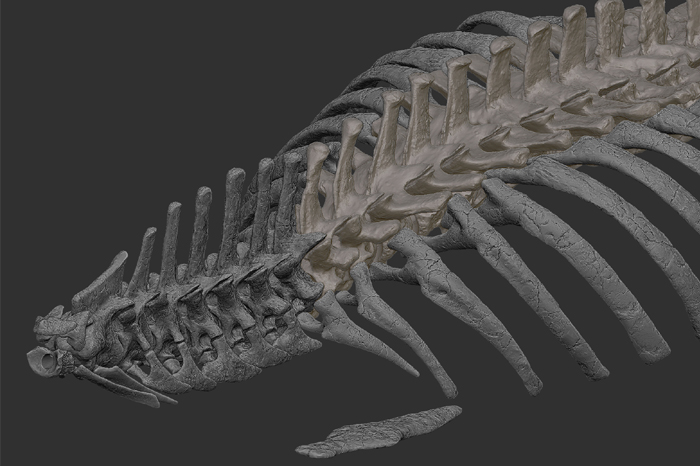

3D printing allows us to create scientifically accurate, high-quality reproductions of fossil material by scanning, digital modelling and 3D printing. We can create exact museum quality dinosaur replicas, which are even more accurate than traditional casts, eliminating the shrinkage and distortion of curing resins. We currently have five large 3D printers, which enable us to print entire skeletons within a workable time frame. Objects larger than our maximum print area can be digitally cut and reconnected once printed. Due to the high accuracy of the printers, reconnected prints go together seamlessly, allowing us to print at any scale. We are up for the challenge of any large print. Our post print processing techniques allow us to maintain surface texture of the original scanned fossil or model. All holes required for skeleton articulation can be pre-drilled digitally with high accuracy which speeds up the articulation process.

3D SCANNING

Shape and colour is captured using the latest photogrammetry software, creating accurate high-resolution 3D scans of any object from smallest fossil to large scale skeletons. The initial non-invasive, touch-free process involves photographing the object to create a digital model, this can be undertaken inhouse under our direction with the use of a DSLR camera, alternatively we can send a technician to undertake the process on your behalf. Once the data is captured and a 3D mesh has been created we can the easily change scale, mirror the object, remove distortion and add broken or missing elements. Skeletons can be articulated digitally and forwarded to the paleontologist in 2D format for review and comment, after which alterations can be easily made. Once the skeleton is complete and modelled bones have approval by the palaeontologist, all bones are saved as individual files which can then be processed for 3D printing, viewed in 3D for study or used in digital format for computer interactives or online.